[You can find Part I – Fact or Fantasy here and Part II – The Organization here]

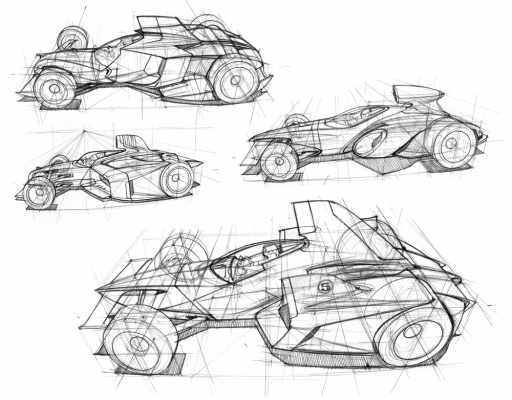

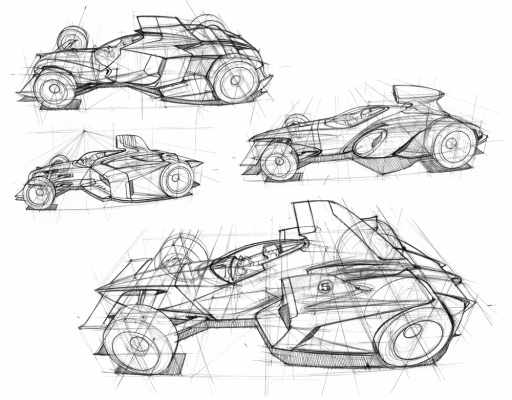

With an organization and facility in place, USF1 will begin the process of designing and building their race car. Every car in Formula 1 is unique, as are the design teams that create them.

The FIA Formula 1 World Championship is all about the car. Although the drivers get most of the media attention and compete amongst themselves for their own championship, Formula 1 teams are, first and foremost, constructors and compete for the constructors championship. This has always been the case. The mission of a Formula 1 team is to design and build the world’s fastest car, in accordance with the rules set out by the FIA. They then compete in a series of races to discover who did the best job. This is the essence of Formula 1.

Ken Anderson is no stranger to car design. He has penned Formula 1 cars and Indy machines. His cars have won in the Indy Car series including victory at the Indianapolis 500. He began his career as a shock designer (called “dampers” in serious race talk) with Fox and Penske so he understands suspension dynamics very well. In Formula 1, he worked with Onyx and Ligier in the late 80’s. He also has experience in NASCAR. Now he is the technical leader for USF1.

Formula 1 cars are designed to a formula, thus their name. Formula 1 is the most sophisticated formula in racing. The formula will specify certain dimensions and weights. It will outline materials that are permitted (or not) as well as the number of wheels, tires, capacity of the engine, etc. How USF1 decides to create their car is their decision and their unique challenge. When complete, it will have to conform to the formula.

The car will be designed by computer, the molds for the carbon-fibre lay-up will also be produced by computer, using CAD-CAM driven devices, The engineers will design each component, model them into 3D images and assemble a virtual car. When they are happy with a component, they will make a mold and produce the part. Computers will also play an important role in testing, from stress analysis to aerodynamic performance, computer software will provide the preliminary test data for the design team. Even predicted track performance will be the task of a computer. This doesn’t eliminate other methods of testing, but it does reduce those requirements and provides the design team the opportunity to test ideas before they commit to the expense of building.

There are only a few pieces of the car that the USF1 design team will not design and manufacture themselves. The engine (and possibly the KERS unit) will be contracted to an existing Formula 1 engine manufacturer who may also supply the gearbox. The brakes will also be purchased from a brake supplier. The dampers and wheels will be manufactured to USF1 specifications by companies that specialize in these items. The ECU is a standard unit design by McLaren and Microsoft. Every other piece of the car will be the responsibility of the design team.

The central structure of a Formula 1 car is the tub; this is the area that contains the driver compartment, the fuel tank, steering mechanism and pedals for the brake and throttle. It will be the structure that all of the other parts will attach to. Carbon-fibre is the material of choice here, as it for most of the parts of the car. This is an expensive manufacturing process for limited production as most of the effort is used to create and prepare the molds. Never-the-less, the advantages of strength and weight make the use of carbon-fibre mandatory to be competitive. The tub also serves as the safety cell for the driver and has to pass the FIA crash test before it can receive a chassis number and be eligible for competition.

The front of the car, the nose piece, is attached to the tub with quick release fasteners. This is an important aerodynamic piece – nose designs for Formula 1 cars vary, as do the thoughts of their designers. The nose piece supports the front wing assembly that provide down-force to the front of the car. There may be several front wing designs to suit different track requirements. This section is also a safety crush zone so the designers have a lot to consider in this area of the car.

The engine is bolted directly to the rear of the tub. Formula 1 engines are “fully-stressed”, meaning that they are an integral part of the car’s structure. The rear suspension will attach to the engine and the gearbox, which is mounted directly to the rear of the engine. This area of the car needs to be well thought out. Oil tanks for the engine and gear box are a dry-sump design, so engine oil is not stored in the crankcase and higher lateral G forces can be withstood withouth any drop in oil pressure.

The rear wing is usually mounted to the gearbox and is a crucial design challenge. It needs to push the rear of the car into the road and produce limited drag. Like the front wing, several designs for the rear wing may be needed.

The suspension arms will be carbon fibre as well. They will be shaped to reduce drag and designed to be as light as possible. The spring mechanism (they could use springs or torsion bars), the dampers, and anti-roll bars will be mounted inboard and actuated by control arms. This moves weight to the centre of the car and reduces drag as well. The ultra-light, forged magnesium wheels of only 13-inched in diameter will hide the even lighter carbon brake assembly.

In these assemblies, the designers will have to create ducts to direct cool air to the brakes. These brake cooling ducts will have to be designed to provide adequate cooling and minimum drag. Each circuit may have different brake cooling requirements.

Once they have designed the structural components, the real fun begins. The side pods and bodywork that cover them and the rear portion of the car have a great influence of drag and down-force. Controlling the air-flow around the car is of vital importance because excess turbulence creates drag and hinders performance. The engineers can’t eliminate this, but they have to control it to the best of their ability.

A flat floor piece will be designed to attach to the bottom of the tub, this piece will control the air-flow below the car. The side-pods house the radiators for cooling water, engine oil and gear oil. Air has to flow though the radiators and be exhausted smoothly. The rear bodywork will reduce drag and funnel air to the rear wing. These are delicate and precise areas in the design of a Formula 1 car.

As you can see, there’s a lot to consider when designing a Formula 1 car, we have only scratched the surface here. There is no right way, there is no right answer to any of the design challenges. Compromise is the only available solution. Compromise what? That is the multi-million dollar question. This is why some teams perform better at certain tracks than others do. This is why some cars are destined for the back of the grid. These are the risks a Formula 1 designer must face.

The finished design will be assembled into a race car by skilled mechanics, by hand. Starting with a bare tub, they will install every component, carefully ensuring that the fit is precise. If something does not fit well, they will go back to the designers to have it modified or re-designed. Once the car is assembled the team will begin to make alternate parts and spares required for the season. Many of the components will be designed to survive only one race weekend.

USF1 will have about 6-months to complete what I just described in a few paragraphs, it will not be enough time, it never is. They will begin to build a car by the end of the summer, so the design can be tested and refined to the best of their ability in time of January track testing. A minimum of three final race chassis will be needed, two as race cars and one as a spare (just in case). By June or July of 2010, they will start the process again, designing their second race car, the one they will use for the 2011 season. Development of the 2010 car may continue as well. The design and engineering department of USF1 will never be short of work.

Now that we have looked at the design challenge facing USF1, in the next installment we will look at what the designers are intending to achieve. We will take a look a the performance requirement of a Formula 1 car.